-

About Company

-

Workplaces

-

Products

-

R&D

-

Investor Relations

ESG

News and Media

Customer Support

Recruitment

Seoyon E-Hwa is a Global Auto Parts Specialized Company.

Establishment

2014 July

(New Establishment after Spin-off)

* Initial Establishment on April 21, 1972

Sales

40,415 (KRW 100M)

(Consolidated Basis)

Number of Employees

939 / 13,727

(Domestic / Overseas)

Workplaces

29

(Domestic and Overseas Plants)

Introducing Various Products of Seoyon E-Hwa.

Introducing the ESG Management of Seoyon E-Hwa.

Here Is the Latest News from Seoyon E-Hwa.

Seoyon E-Hwa Invites Global Talents to Join Us.

Career INFO

Introducing various positions

where you can develop and

demonstrate individual competencies

Talent

Talents of Seoyon E-Hwa who complete tasks responsibly with passion, creativity, and innovation

HR System

Fair and transparent HR system from individual and organizational perspectives

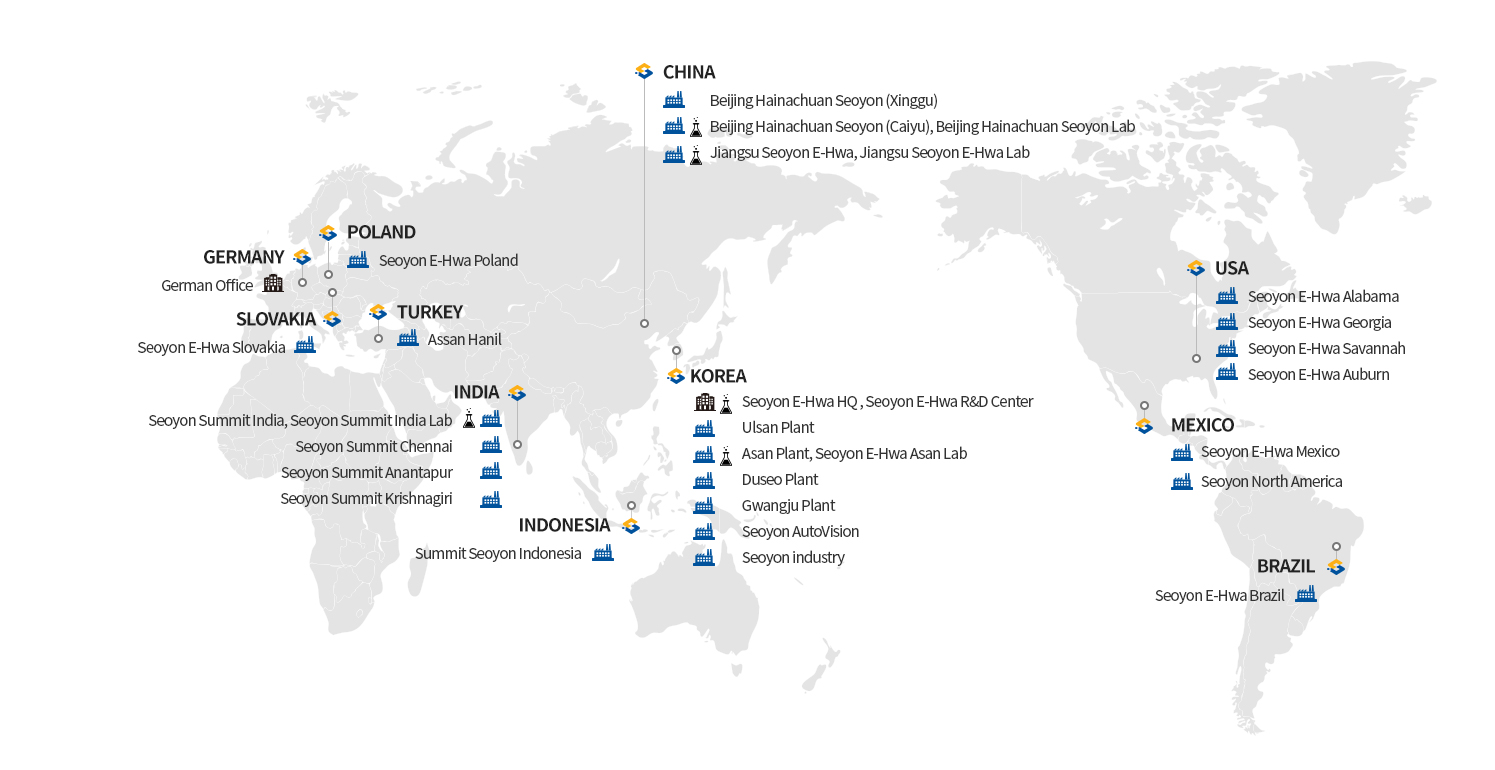

Introducing the Global Network of Seoyon E-Hwa Taking a Leap into the World.

24

Production Plants

5

Labs

2

HQ/Offices

29

Production Plants

4

Labs

1

HQ/Offices