Quality

Management

- Quality Management

- Quality Policy

- Quality History

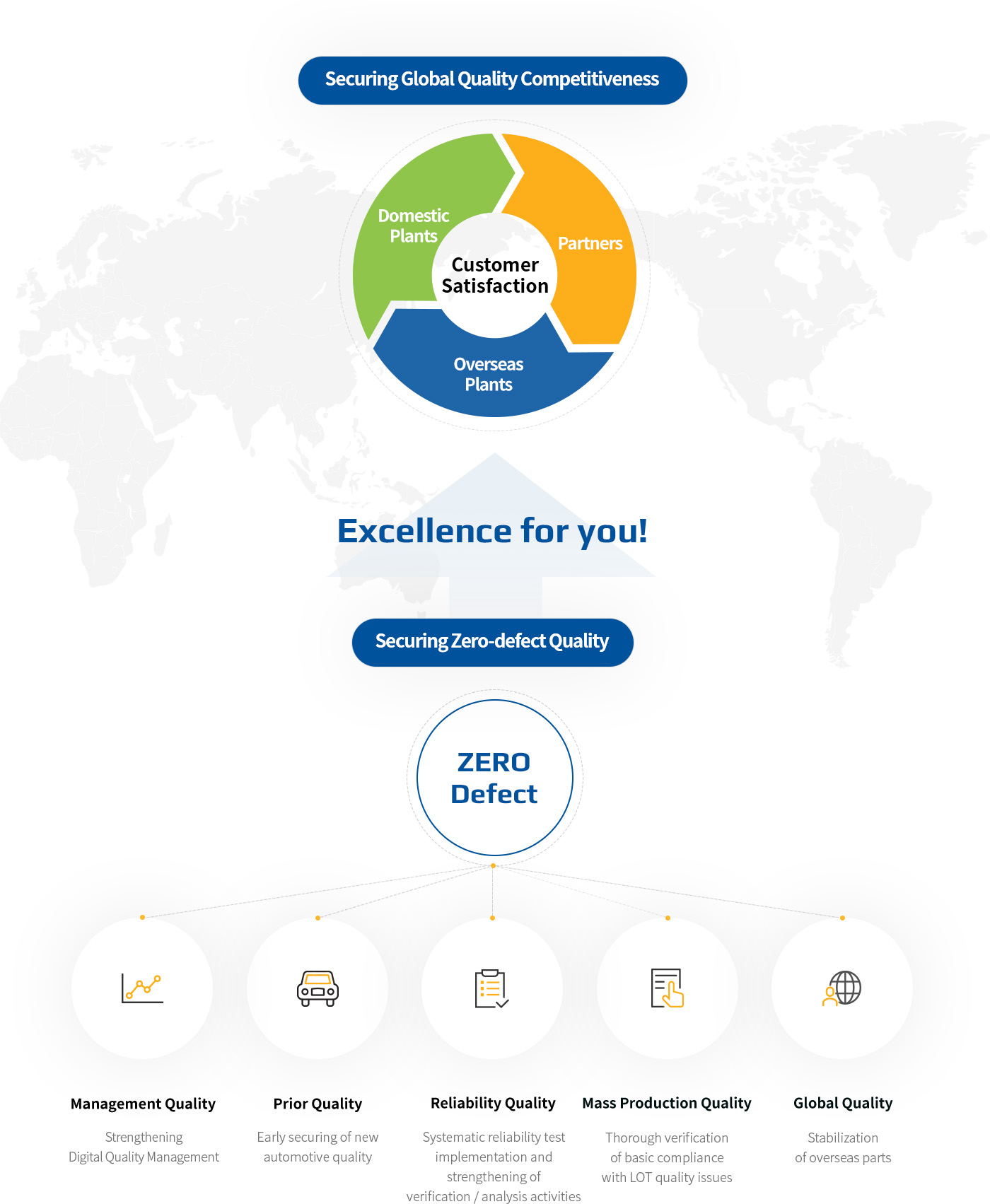

Quality Management for Customers!

The best quality management that Seoyon E-Hwa purses is customer satisfaction.

Seoyon E-Hwa has established a quality policy to supply perfect quality products to customers and established IATF 16949 (Quality Management System) to continuously improve quality to achieve the best world-class quality and customer satisfaction.

- · Global Quality

- Application of global quality system and standardization of processes

- · Smart Quality

- Implementation/operation of global quality network based on big data

- · Intelligence Quality

- Intelligent and smart quality management system operation

-

Global Quality

Seoyon E-Hwa has established a quality management system for the automotive industry (IATF 16949) for sustainable global quality management activities and is carrying out continuous quality improvement activities. Also, to comply with the quality management system requirements of global OEMs, we have secured professional manpower and promoted process standardization to provide quality that satisfies all customers.

-

Smart Quality

Seoyon E-Hwa has production bases in Korea, the Americas, China, Europe, and India, and numerous engineers are accumulating experience and know-how in a range of environments from product design to customer delivery and use. These valuable experiences and know-how are being promoted as activities in which data is collected and analyzed through a “big data system” and applied to new automobiles and verified.

-

Intelligence Quality

Seoyon E-Hwa is promoting quality innovation for data and information-oriented digital transformation from human-centered cognition and sensory-based determination. For a mid- to long-term project called the “Establishment of an Intelligent Manufacturing Process,” we are promoting changes for intelligent quality management by applying a vision inspection system and automatic inspection device.

Seoyon E-Hwa, a leader in the automotive interior parts industry, is striving

to secure global quality competitiveness that satisfies both domestic and overseas customers

through continuous innovation and improvement activities based on core technology development, a realization of perfect quality, and substantiation of management quality, with a management philosophy of “contributing to the happiness of mankind by creating the best products and services based on talents of the highest level.”

Seoyon E-Hwa has been continuously pursuing innovation and

improvement activities to secure global quality competitiveness.

-

2023 ~ 2021

- Received 'Partner of the Year' Award in the new car development sector from Hyundai Motor Group

- Awarded with the 'Supplier Of The Year' Grand prize at Hyundai Motor and Kia 『Partnership Day』

- Inducted into the 『Hall of Fame』 for companies with excellent quality competitiveness at the National Quality Management Competition

- Presidential Award Winner at the National Quality Management Team Competition (~24 consecutive years of winning)

- Selection of Outstanding Partner Companies for Achieving 100-Day Mission Zero Defects

· 2021 : GL3 · 2023 : SX2

-

2020 ~ 2016

- Seoyon E-Hwa Slovakia acquired EFQM 5 Star

- Selected as Quality Circle Excellent Workplace

- IATF 16949 transition certification

- ISO 45001 transition certification

- China CQC Resource Certification (formerly China Compulsory Certification, CCC)

-

2015 ~ 2011

- Reorganized into Quality Management (Quality Control Division and Quality Management Division)

- Received the 2015 National Quality Master Presidential Award

- Received the 2014 Slovakia National Quality Award

- AEO certification in Export Sector

- OHSAS 18001 certification

- Received product certification from Taiwan VSCC

-

2010 ~ 2006

- Reorganized into Quality Management Division (Quality Management Team and Quality Control Team)

- Received the 2014 Slovakia National Quality Award

- Received the National Quality Innovation Award (Six Sigma Innovation)

- Received China Compulsory Certification(CCC)

-

2005 ~ 2001

- Division system introduced (Customer Support Division)

- Single Part Per Million (Single PPM) certification

- ISO/TS 16949 certification

- IISO 14001 certification

- Six Sigma introduced

-

Before 2000

- TPM introduced

- QS 9000 certification

- Silver Tower Order of Industrial Service Merit Award for Quality Management Innovation

- 100 PPM certification

- Team system introduced (Quality Center operated)

- ISO 9001 certification

- Designated as Class 1 Quality Management Company

- A department in charge of TQC newly established (quality circles and proposal)

Results of Maintaining Quality Competitiveness Activities

17th Selection

(2004~2024)

Consistent Award Recipient from the 23rd to the 50th Editions

(1997 to 2024)

Acquired a total of 27 times

(2005~2024)