Applied

Technology

Differentiated technologies are applied in relation to the manufacturing of our

products for the performance / quality / reliability required by customers.

New Automobile Development Process

Key Customer Requirements

Production Technology Capability

Company-wide Resource Management Capability

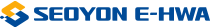

Countermeasures to Key Customer Requirements

Securing customer trust by achieving quality goals through pre-verification (Four Major Tasks, VOC)

-

Injection Technology

- Automatic product extraction/weight measurement/Gate cutting using articulated robots, Managing resin through barcode system

-

Injection Automation

-

Resin feeding by barcode info

-

Automatic Opening of Material Tank

-

Automatic Color Change

-

Molding Technology

- Cold/Hot Forming : product pressing forming through preheating NVH item material and pressing

- Waterjet cutting and Automatic transfer :

Using formed SOFT TRIM, automatic transfer for cutting the product and f/proof system

-

Painting Technology

- BUMPER and In/Exterior

-

Vision Inspection

-

Plasma flame treatment

-

Painting Automation

-

Painting Inspection

-

Assembly Technology

- Plastic Bonding

-

Halogen

-

Ultrasonic Welding

-

Hot Air

- Automatic Product Transfer System (conveyor)

-

MMC

(Mono-rail Modular conveyor) -

FREE FLOW

-

OVAL

- Inspection System

-

Vision Inspection Using UR Robots

-

Vision scanning inspection

-

System TOOL

(Tapping screw torque management)

-

Logistics Technology

- SEAT Automatic Loading

- Door Trim Automatic Loading/Unloading by using AGV

- Automatic Equipment Specification Change by using AMR

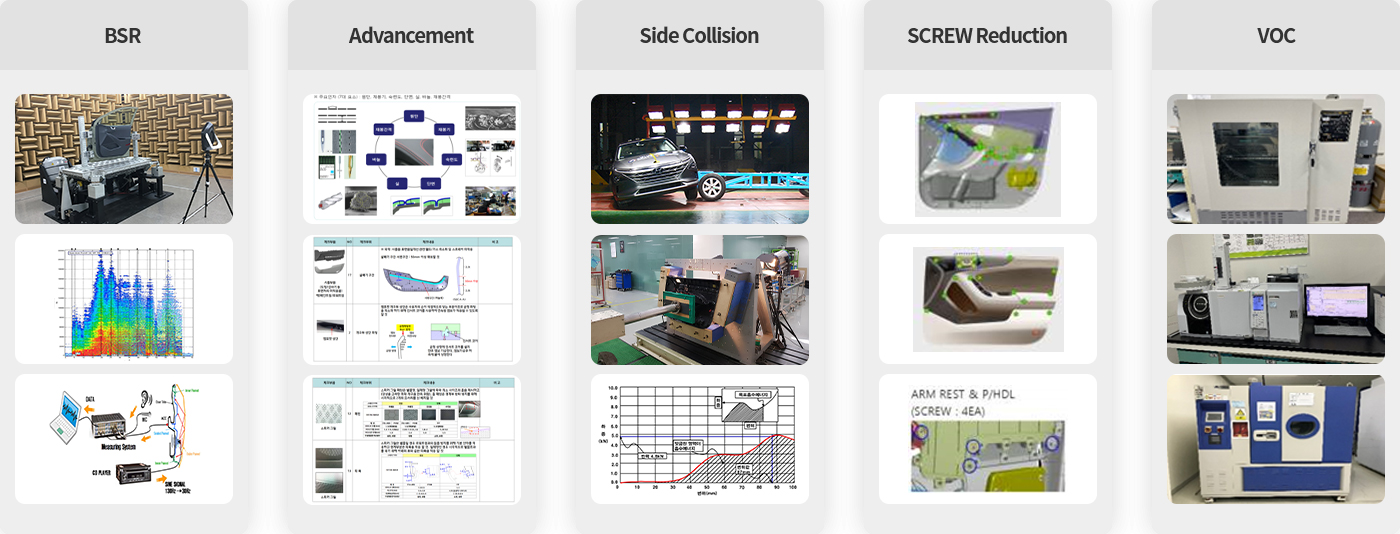

Seoyon E-Hwa Network System

Project Schedule Management Using Company-wide Resource Management

- 01 PDMProduct Data Management

- 02 SCMSupply Chain Management

- 03 MESManufacturing Execution System

- 04 GQMSGlobal Quality Management System

- 05 ERPEnterprise Resource Planning

- 06 GPMSGlobal Project Quality Management System

- 07 SIMSSeoyonehwa Intellectual Management System