Research

Fields

Seoyon E-Hwa lab is striving for technology research and product development

by focusing all its capabilities on the fields of product design, new methods,

new materials, prior verification, design, and product development.

- Product Design

- New Methods

- New Materials

- Pre-verification

- Design

- Product development

STEP 01

B/MARKING

An operational process that identifies product trends and reflects strengths by acquiring/analyzing products that are similar or superior in design and method

STEP 02

Design

A series of activities to determine the shape, size, material, and method and make drawings so that optimal products that satisfy price, function, performance, and quality can be easily manufactured

STEP 03

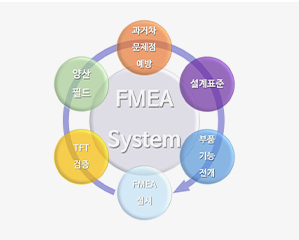

DFMEA

An analytical technique used for the purpose of eliminating/reducing the chance of potential failure by identifying potential failure types and effects of a product or process through failure mode effect analysis performed for product design in the design development stage

STEP 04

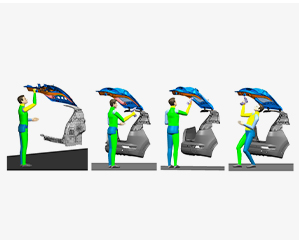

DFSS/DPA

A virtual design verification system that shortens the development period and reduces costs by using a digital verification method for interference/assembly/operability between parts using design data, not products

STEP 05

Analysis

An activity to verify in advance whether it is safe even in the most unfavorable situation when the variable/external force expected by the designer is applied when a structure in the design stage is actually manufactured

STEP 06

Verification

A step to pre-evaluate the completeness of parts through rapid prototype (RP) product production before prototype production

STEP 07

PROTO

A step to verify the assembled automobile using simple assembly jigs and parts production using molds, etc., according to the design drawings

STEP 08

Verification/Test

Verifying that the designed product satisfies customer needs and functions properly as a product. A step to verify the reliability of whether the material of the product is appropriate (MS) and whether it meets the required specifications (ES)

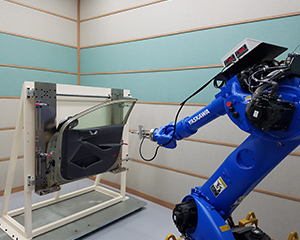

Research on Methods (New technology & Production method research)

Development of new technologies/methods for the structures and manufacturing methods of automotive interior/exterior parts

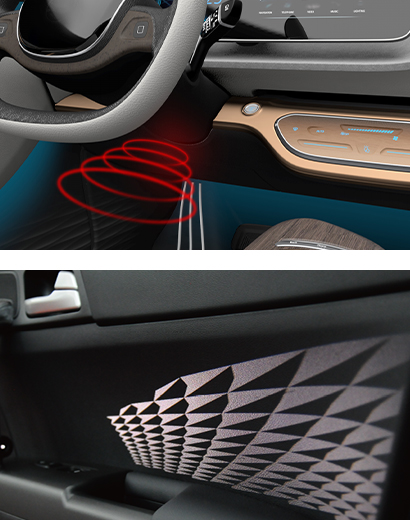

Human-Interface new technology

- Morphing surface switch

- Haptic touch hidden display

- Soft-type touch switch

Interdisciplinary integration technology

- Local proximity air-conditioning system

- Surface emitting lighting with soft-trim

- Multi – focused infinite mirror lighting pattern

New production method

- Ultra-precise mold control for Foaming injection

- Core rotation technology in co-injection mold

- High-sensitivity fabric insert injection technology

Advanced materials research

Review of the new material application of automotive interior/exterior parts and evaluation of various material specifications

Light-weight

- Engineering plastics replacing steel

- GFRP/CFRP light-weight composites

- Foaming technology & Light-weight additives

Eco-friendly

- Recyclable & post-consumer materials

- Low VOCs materials & Carbon foot-print

- Bio-composites & Natural fiber composites

High-performance

- Materials for EV battery system

- Materials for integral molding process

- Excellent scratch-resistant & durable materials

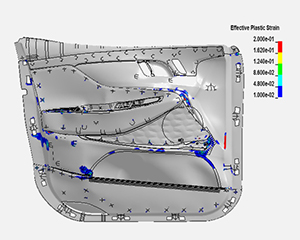

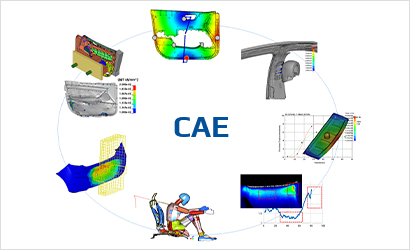

Pre-verification

- Predicting quality and performance of products using CAE

- Evaluating performance of products by various tests

CAE simulation

- Crash analysis

- Vibration analysis

- Stiffness/Strength analysis

- Injection molding analysis

- BSR analysis

- Ambient lighting analysis

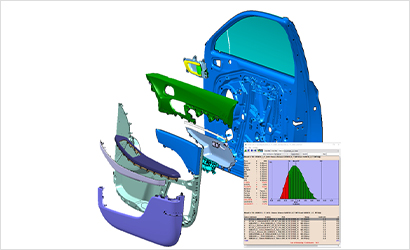

CAD DATA verification

- Digital Pre-Assembly verification

- Tolerance analysis

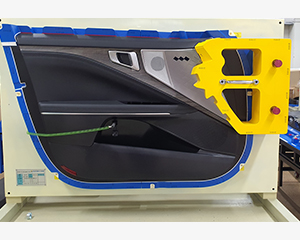

Product assessment

- Side impact(Sharp edge) test)

- BSR test

- Abdomen peak force test

- Ambient lighting test

Design

- Future mobility user environment analysis and user experience (UX) research

- Biz model production and customer proposal

- Joint development of advanced design with global automobiles

Study future mobility

- Research future mobility trend

- Analysis customer’s needs

- Development new technology

Business model

- Apply new technology/process/material

- Propose models for clients

- Customer acquisition

Client cooperation

- Fulfill client cooperation project

- Collaboration for developing future mobility

- Apply new technology for car interior

Product development

- Mass production feasibility review of design data/methods/material

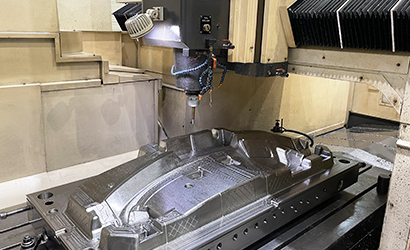

- Quality assurance activities for parts (Appearance, dimensions, functions, and reliability) and molds

- Molds/Guages specification review and development

Project Management

- GPMS task execution/management

(GPMS : Global Project Management System) - S-Mold task execution/management

(S-Mold : Seoyon Molds Development System)

Parts Development

- Parts development planning

- Parts production and supply response

- Preliminary review and assurance of mass production capacity

- Parts quality assurance (Appearance, dimensions, and reliability)

Molds Development

- Quotation reception and company selection

- Feasibility review of design data and molding production

- Molds making & inspection

- Molds quality assurance (operability and durability)